There are times when standard industrial products are not in accordance with the need for manufacturing. Whether special measures or materials or even industrial equipment that are fully reconnected are needed, most companies will find themselves in the position they need to order industrial product fabrication. There are many factors to consider when shopping for unique equipment solutions, and we will take the time to touch them in this article.

The right company for use for special work is usually companies that are suppliers of industrial products that also have extensive machining skills in locations. This supplier has knowledge of various industrial equipment, as well as the ability to change existing stocks to fit customer specifications. Let’s look at some specifics for the best custom work solutions.

Batch size and machining technology

Reproducing is usually a labor solid project for small batch size. For this reason, many machining stores charge premium fees when they have to regulate their production tools to make a handful of goods. To find a cost-effective solution, it pays to shop around between different suppliers who are willing to provide small batch size on industrial equipment that is reworked or fully new products without excessive. This often can be achieved through the same supplier that usually provides industrial products and can offer special jobs as a service to maintain good relations. This fact must remain true whether a company in binding is only one work reworked to repair the engine or even a system that is fully redesigned and reworked for delivery.

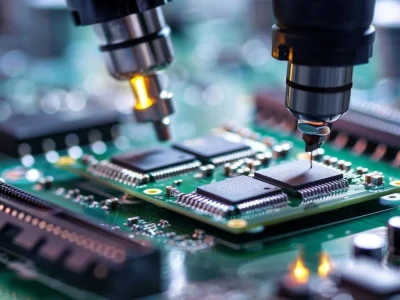

One way to find a company that can offer a small batch size on all types of work without charging premium is finding a machine store that utilizes a network that can be programmed (CNC) numerical control. CNC devices are able to be programmed to run batch jobs through instructional blueprints, such as CAD images. They can then run the fabrication process on several or as much as needed. In addition, the stored blueprint allows the machine shop to return and make more pieces easily and even utilize that knowledge for other special work. Overall, cnc machining will reduce production costs to keep the price of industrial products ordered in a small batch more reasonable.

Although there are many craftsmen in small shops that can make amazing works with hand tooling methods, CNC devices also offer precision that can be reproduced. For special orders larger with strict requirements, these machine shops will provide fast and high-quality services you need.

Special products and industrial equipment recharged

Another aspect of the right store for the services needed by batch work is the ability to fabricate from a completely new product and be able to process and modify existing industrial equipment. Having both options is very important to find the right solution for a problem. Some problems require simple machine components, and others may call for a completely new substitute.

For this reason, suppliers are often a good choice because they have a large inventory of existing products to work as a basis for new rework or fabrication. Modifying the current inventory with different sizes or shapes will be much cheaper and time consuming than starting from the beginning. When ordering a reworked system, many standard items can enter into their creations to limit the number of new parts.

Design process

By definition, special work always requires a re-level and technique. Not every company has personnel or the ability to conduct large-scale designs, compilation, or engineering and architectural work needed to correct problems or to make customized solutions. Therefore, through companies that are able to carry out the design process eliminate the need for mid