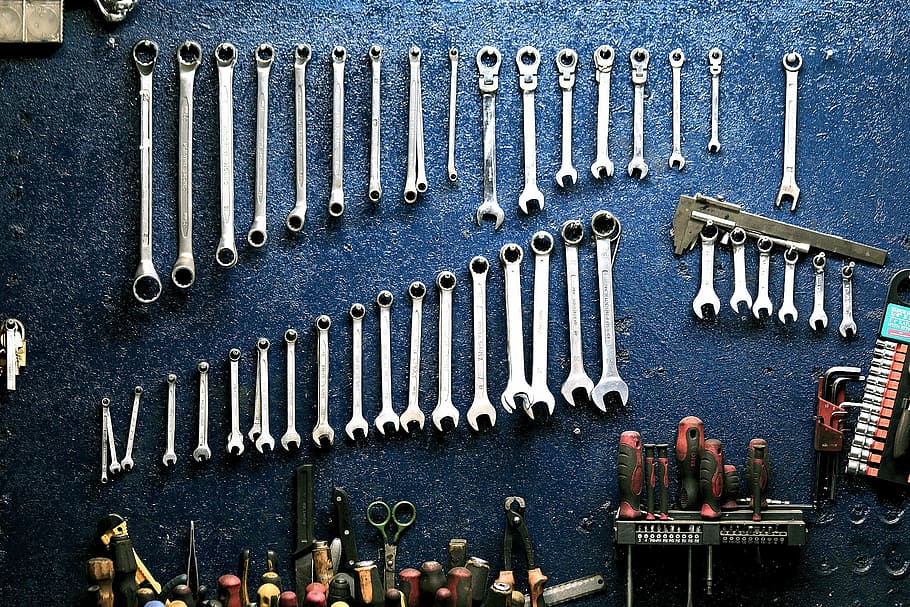

From the field of construction to the field of factories, electrical appliances are special industrial tools that are inevitable to industrial work culture. However, not all power industrial tools can be used for all purposes.

For example, exercise is a type of electrical tools commonly used for all-round work, without any area that helps use practice. Other electrical devices such as Jigsaw or various types of nailers are those under the category of special power tools. These industrial tools are used and form an important part of work because of the amount of efficiency given to workers. If we quote an example outside the construction genre, then we can say that the function of industrial equipment through other manual tools is the same as the sewing machine function carried out on the hand of the clothes sewn. Just like sewing machine sewing clothes at a faster level with increasing accuracy and quality is complete, something that is not achieved with hand stitching clothes. Similarly, the power industry tool makes industrial worker efforts less burdensome than what should be.

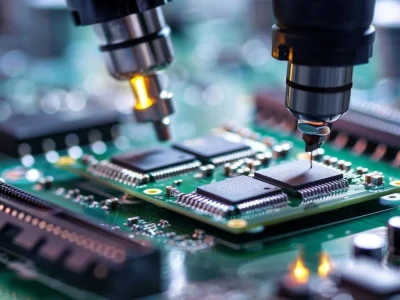

Two types of power industrial tools available on the market are stationery and are portable. These two types of electrical appliance can be used with the help of three different methods. These three methods include the use of electric motors, compressed air or gasoline engines. Electric motors are used for ordinary handheld tools. This is followed by compressed air which is generally felt in a tool such as paint and mailer sprayers. Gradually observing that some standard tools are being used by compressed air by certain companies. One example of a company like that is Campell Hausfeld. The use of generators is important in terms of electrical appliances that come with a rope. There is also the availability of battery-powered tools that give workers profit to bring them to different locations according to requirements.

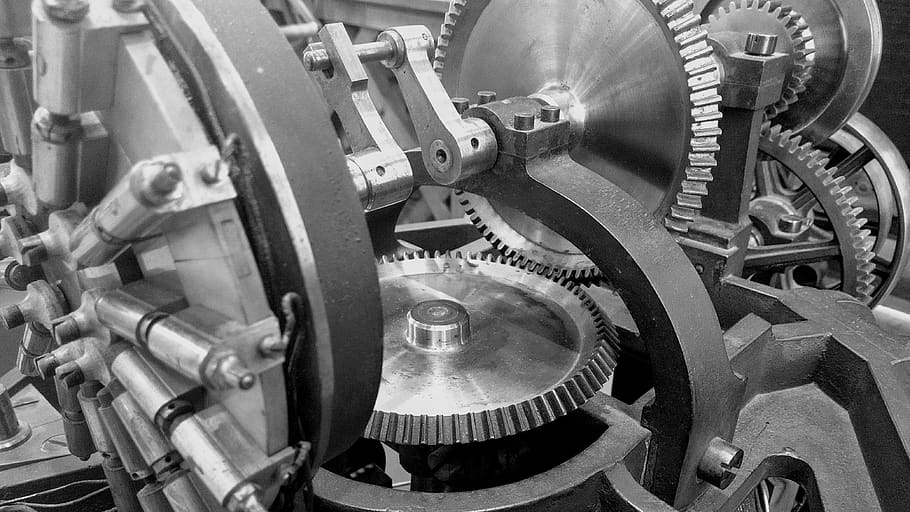

Losses accompanied by this power industry tool are the number of vibrations and noise made by these tools. To prevent this problem, certain companies now come with advanced technology, which reduces the amount of vibration and good emanating from these industrial tools. Lack of vibration helps workers to have a better grip on the previous tool impossible or achieved with difficulty.

It must be remembered that all of this forms an inevitable part of industrial workers. Even a small work like making a hole or pieces becomes easier with these electrical tools. These tools are the main equipment responsible for reducing the time he works together by increasing the speed of efficiency. Because these two aspects – speed and time are the most vital elements in any work environment, then the use of power industrial tools is one of the main assistance to achieving the industrial task of innumerable forms.