Wireless industrial pressure sensors are often found in applications for monitoring machine status and systems in the manufacturing industry and in process control. In addition, the fact that this device communicates with the control system through wireless communication means that they can be used in various equipment remote control. General design for this pressure sensor, such as Keller’s pressure sensor, is based on the principle of piezoresistance where material resistance is directly proportional to the pressure applied to the material. There are various wireless industry sensor applications, due to the fact that they are wireless offers several benefits.

Some of the benefits of wireless industrial pressure sensors include circuit integration, network ease, miniaturizing transducers, better signal-to-noise ratios, and multi-point sensors. The device can also be used to determine bottled pressure in the petroleum industry. How do various industries utilize this sensor network, including differential pressure transmitters? Wireless sensor networks can be applied to examine different process variables in petroleum production activities, monitoring process variables that are different in manufacturing, and overseeing many process parameters in waste / waste water facilities. There are so many possibilities for using this sensor network but observed that they tend to be used frequently in the industry where materials flow, such as in the chemical industry, metal industry, paper and pulp industries, beverage industry, and the food industry.

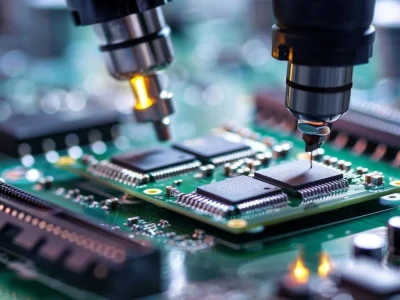

As mentioned above, the basic principle of the sensor is that the current flowing through piezoelectric material is proportional to the amount of pressure. For regular pressure transducers, this electric current moves through an electric cable. However, a more convenient setting is the use of wireless pressure sensors. It is equipped with the ability to make radio signals that transmit information to the control panel or computer. Some specific applications of wireless pressure sensors in the industry include leakage testing, liquid or gas measurements, and examine gas pressure and liquid on certain machines to ensure the right operation and security. This device can be a differential pressure sensor, closed sensor, measuring sensor, or absolute pressure sensor.

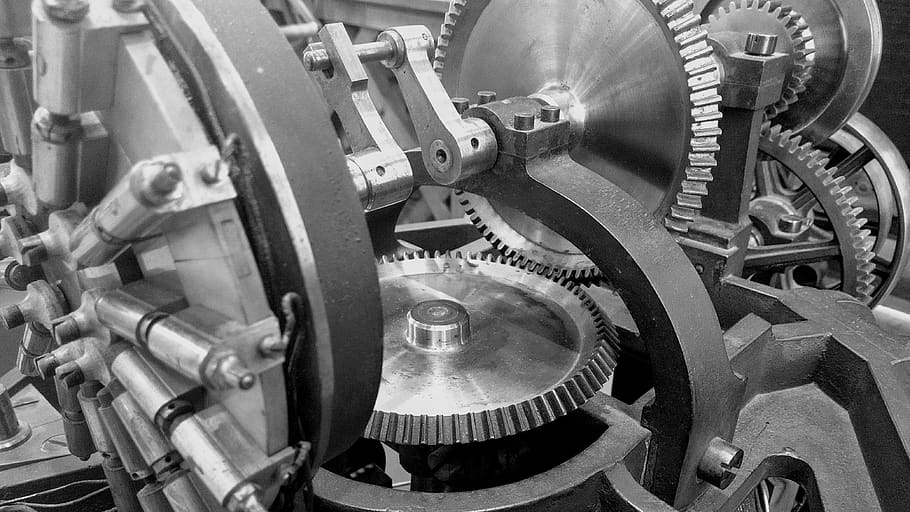

The wireless industrial pressure sensor uses the style collector to detect pressure. This sensing diaphragm can be in the form of potentics, piezoelectric, optical, capacitive, electromagnetic, or piezoresistif. This system can be classified below the direct pressure measurement category. On the other hand, it is also possible to measure pressure indirectly. These sensors make other variables measurements, such as ion flow, gas thermal conductivity changes, and changes in resonance frequency in the sensor or transducer section. Meanwhile, the industrial processing system usually requires a large number of pressure detectors. Thus, wireless sensor networks are often used to allow computers to carry out monitoring and analysis activities. In this way, process control can be automated for more efficient industrial processes and to minimize costs.