Manufacture, a term that has been intrinsic to human progress, is more than just the process of making goods. It encapsulates a history of transformation, from small-scale artisan workshops to the sprawling, automated factories that define much of our modern economy. The act of manufacture—once a singular, localized activity—is now a global force that drives industries, shapes economies, and reflects the culture of innovation. At its core, manufacturing is about turning raw materials into finished products, but this simple definition belies the complexity and dynamism of the field. From the manual labor of early civilizations to the precision of contemporary high-tech production, the history and future of manufacturing are deeply intertwined with technological advancements, sustainability, and the evolving needs of society.

The Evolution of Manufacture: From Craft to Machine

The story of manufacturing is inherently tied to human ingenuity. In ancient times, the manufacture of goods was a highly localized activity. Artisans and craftsmen played pivotal roles, creating everything from pottery to tools to clothing using basic techniques passed down through generations. These processes were often slow, labor-intensive, and reliant on manual skill. The resulting products were not only functional but often carried the unique marks of their makers.

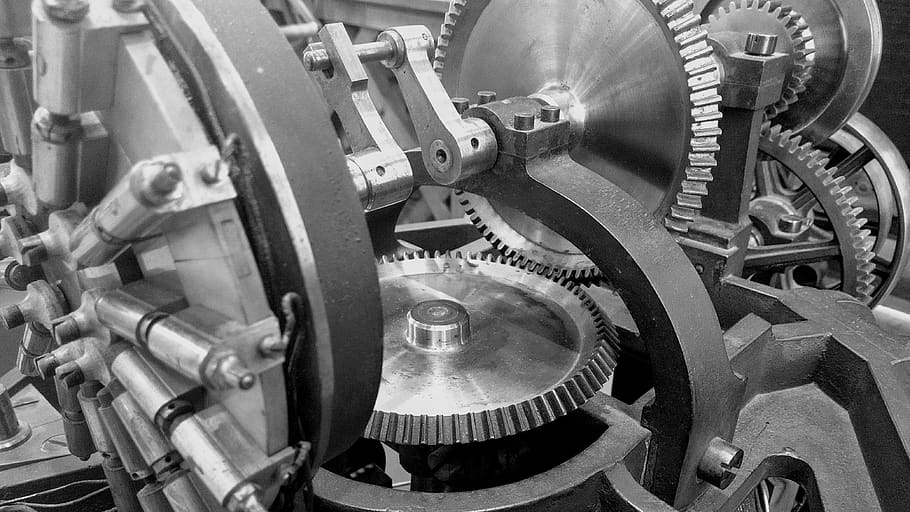

It wasn’t until the Industrial Revolution in the 18th century that manufacturing underwent a seismic shift. Inventions like the steam engine, spinning jenny, and power looms revolutionized production, allowing for goods to be made in quantities far beyond the capabilities of manual labor. Factories became the backbone of economies, and mass production emerged as a cornerstone of industrialized nations. The efficiency and speed brought by mechanization not only fueled the expansion of industries like textiles, steel, and automobiles but also spurred economic growth and urbanization, shifting populations from rural to urban centers.

The rise of mass production, epitomized by Henry Ford’s assembly line, ushered in an era where cost-effective production could make goods more accessible to a broader population. Standardization, interchangeable parts, and high-volume output became the dominant forces of manufacturing, shaping everything from consumer goods to machinery. Yet, even in this age of industrialization, there was still an element of artistry in the process—the fine details of design, the planning of systems, and the consideration of form and function were still vital.

The Modern Manufacturing Landscape: Efficiency, Automation, and Precision

In the present day, the landscape of manufacturing has evolved again, driven largely by technological innovation. From precision engineering to the incorporation of digital technologies, modern manufacturing is marked by an incredible level of sophistication and efficiency. The rise of automation, robotics, and artificial intelligence (AI) has led to what many call the “Fourth Industrial Revolution”—a wave of change that promises to redefine not only how products are made but also how companies operate.

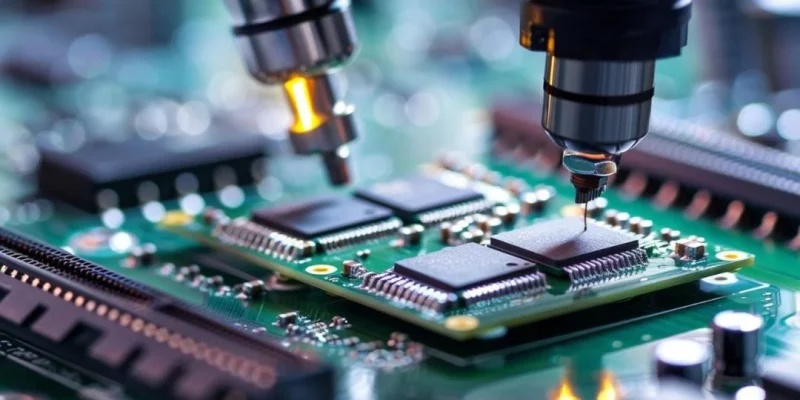

Automation has become central to modern manufacturing. The once manual tasks of assembly, inspection, and packaging have been replaced by robotic systems capable of executing these tasks faster, more accurately, and with fewer errors. Robots, equipped with AI and machine learning capabilities, can now adapt to changing conditions, allowing for greater flexibility in production. Whether it’s a car factory with hundreds of robots assembling vehicles or an electronics plant where machines pick and place components on tiny circuit boards, automation is the backbone of modern manufacturing efficiency.

Additionally, digital tools have revolutionized product design and production processes. With advancements in computer-aided design (CAD) and simulation software, manufacturers can now visualize and test their products in a virtual environment long before they reach the factory floor. This allows for rapid prototyping, improved testing, and the ability to make design changes on the fly—speeding up the process from concept to production. Furthermore, the rise of additive manufacturing, or 3D printing, has opened new frontiers in product customization and innovation, enabling manufacturers to create complex, custom-designed products in small batches with minimal waste.

The growing use of data and the Internet of Things (IoT) in manufacturing is another transformative development. Smart factories, equipped with interconnected machines and sensors, are capable of tracking and analyzing data in real-time, allowing for predictive maintenance, inventory management, and supply chain optimization. This data-driven approach not only enhances efficiency but also provides manufacturers with valuable insights into their operations, leading to continuous improvements and reduced costs.

Sustainability and Ethical Manufacturing: A New Imperative

While technological advancements have significantly enhanced the capabilities of modern manufacturing, the industry also faces growing pressure to address its environmental and ethical impact. The traditional manufacturing model, often characterized by resource-intensive processes and significant waste, is increasingly being scrutinized by consumers, governments, and advocacy groups alike. As global concerns over climate change, resource depletion, and environmental degradation mount, there is a compelling need for manufacturers to adopt more sustainable practices.

Sustainability in manufacturing is multifaceted, encompassing everything from the responsible sourcing of raw materials to the reduction of waste and energy consumption. Companies are increasingly turning to renewable energy sources—such as solar, wind, and geothermal—within their factories to power production processes. Meanwhile, innovations in materials science are allowing for the creation of products that are not only more efficient but also less resource-hungry, reducing the environmental footprint of production.

A key area of focus in sustainable manufacturing is the adoption of a circular economy model. In traditional linear manufacturing, products are created, used, and then discarded, leading to waste. Circular manufacturing, however, seeks to close the loop by designing products that can be reused, refurbished, or recycled, thus minimizing waste and extending the lifecycle of materials. Companies like Patagonia and IKEA have made significant strides in promoting circular production practices, ensuring that their products are made with recyclable materials and can be repurposed at the end of their life cycle.

Alongside environmental sustainability, ethical considerations are also at the forefront of modern manufacturing practices. The globalized nature of production often raises questions about labor conditions, especially in countries where workers are paid low wages and subjected to poor working environments. As consumers become more conscientious, there is an increasing demand for transparency and ethical standards in manufacturing. Certifications like Fair Trade and B Corp have emerged as benchmarks for companies committed to ensuring ethical labor practices, fair wages, and safe working conditions throughout their supply chains.

The Future of Manufacturing: Innovation, Customization, and Global Collaboration

Looking ahead, the future of manufacturing promises to be shaped by an even greater blend of innovation and collaboration. One of the most exciting developments is the growing trend of mass customization. As consumer expectations for personalized products continue to rise, manufacturers are exploring new ways to provide bespoke goods without sacrificing the efficiency of mass production. Technologies such as AI, robotics, and 3D printing are making it possible for companies to offer tailored products—whether it’s personalized sneakers, custom-built furniture, or made-to-order electronics—at a fraction of the cost and time that was once required for such bespoke creations.

Furthermore, as the world becomes more interconnected, global collaboration will play an increasingly crucial role in the manufacturing process. The sharing of knowledge, resources, and technologies across borders is enabling companies to tap into the expertise of various regions while also addressing challenges such as supply chain resilience, geopolitical risks, and market volatility. Collaborative platforms and partnerships between manufacturers, tech companies, and research institutions are paving the way for innovations that can drive the next wave of manufacturing excellence.

Finally, as sustainability and ethical practices continue to be at the forefront of consumer concerns, the manufacturing industry will need to further integrate these principles into every stage of production. This will require not just technological innovation but also a shift in the way businesses view their role in society. Manufacturers that embrace sustainability, ethical labor practices, and technological advances will be well-positioned to lead in the future, creating products that not only meet consumer needs but also contribute positively to the world around them.

Conclusion: The Enduring Power of Manufacture

Manufacturing, in all its forms, is an essential driver of economic growth, technological advancement, and societal progress. From the manual craftsmanship of early civilizations to the high-tech, data-driven processes of today, manufacturing has continually evolved to meet the changing needs of the world. The future of manufacturing promises even greater innovation, from customized, sustainable production to smart factories powered by AI and IoT. As we move forward, it is clear that manufacturing will continue to be a key pillar of modern society—shaping not only the products we consume but also the world we live in. In embracing new technologies and responsible practices, manufacturers will have the opportunity to not only redefine industry but also contribute to a more sustainable and ethical future for all.